Why is there a need for a smart solution for the process of tank level monitoring and analysis?

When handling large volumes of fluids, refineries, chemical plants, and bulk liquid storage, terminal operators must know precisely how much product is in any given tank. When products change hands or move in or out of tanks, the monetary values and safety risks can be enormous. Despite this, the devices and systems used to gauge tank contents often receive insufficient attention.

One of the main reasons for this is that those responsible for inventory management and custody transfer often believe the technologies in these systems are static and there is little to gain from making improvements. As a result, they settle into familiar but ineffective work practices, believing the inefficiencies, safety risks, and uncertainties they deal with are part of their daily life.

Many facilities still depend on manual procedures and inefficient systems, and large numbers of devices don’t operate accurately or reliably enough. Making the complete process of Tank level analysis or monitoring operation cost and time expensive.

What is SOTA X?

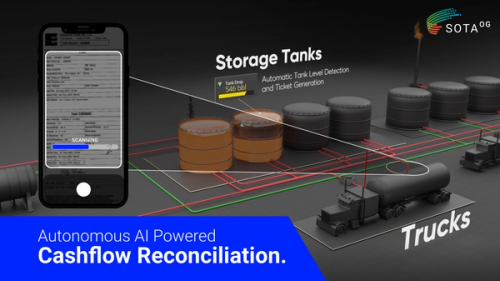

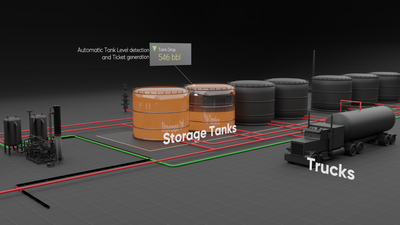

SOTAOG's IIoT-based Solution, SOTA X based on advanced ML and AI algorithms for Tank Level Monitoring capture real-time production data from embedded sensors, process the data into information on the IoT Platform and provides the relevant information to the users on its mobile/web apps. SOTA X for Tank Level Monitoring eliminates manual data entry by providing a solution that helps to monitor your inventory levels without human intervention. It also provides you with a cost-effective way of monitoring your inventory levels as well as enhancing transparency into your operations by providing real-time production data.

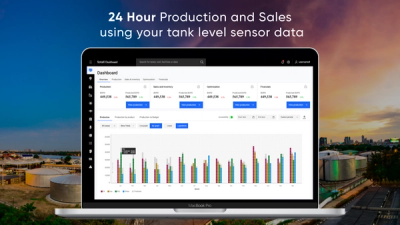

SOTA X uses AI-powered OCR to read and compare the real-time data of tank levels. SOTA X can examine your tank level information utilizing AI and ML calculations to assess your 24-hour production and sales. It assists you with predicting your losses and gains in operations. With this huge pile of information, you can eradicate a huge human capital requirement which results in a large cut in operational expenses. While keeping real-time control over your inventory. Our solution empowers the operators with the ability to remotely monitor the inventory levels inside tanks. Supervisors are immediately alerted if the level inside the tank goes below/beyond the allowed limits.

With our real-time predictive optimization solution, you'll be able to keep track of your inventory levels in real-time, while keeping your operators in the loop at all times—allowing them to make decisions based on accurate information

Our Deliverables?

- SOTAOG observes and uses the real-time Oil sales price - Which gives a real-time and accurate amount of money they are making for each barrel they sold.

- Providing auditable and defensible data at the time of payment, reconciliation, etc. This can be presented visually and provided as a report.

- SOTAOG can also help close the gap between forecasts vs. actual production totals.

- We can proactively identify sensors/meters that are offline or recognize measurement or quality errors.

- We can leverage the financial analysis to look at a granular level of the operational cost/BBL and look at the distribution matrix to optimize it. Example underlying optimization rules could be based on lowest cost, highest revenue, Reservoir parameters, etc.

- We can automate the distribution matrix of wells Pipelines, based on 1st Engineering principles. This will lead to the highest flow rate (which primarily depends on real-time pressure, and temperature) and ensure maximum profitability. We have models built which can do forecasts based on real-time data.

- We can also drive additional insights on the Wells flow rate with the Suction pressure (pressure is a manual entry at this time) of the pumps.

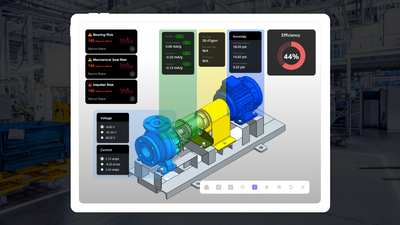

- We can provide Pump performance metrics and with good data, we can predict when a Pump could go down based on the signature of the real-time data.

Our Pricing?

To demonstrate our value, we are willing to conduct a $0 pilot to showcase the affordability of our IIOT solution. Price starts at 30 dollars per tank per month, volume discounts are available, and 0 billable hours.

Our client story

SOTA X's predictive analytics have been implemented to help analyze the number of barrels sold and track tank levels, meters, and ML-based rate of change calculations, allowing for further analyses that have enabled the organization to coordinate more effectively with their vendors. When we examined one of our client cases and researched, our examination showed discrepancies in the number of barrels the company(client) had shipped and the number for which the payment had been made. When we went over this case and researched, our examination mirrored that the organization had sold 129,598 barrels however they were just paid for 128,396 barrels. Furthermore, if we calculate the cash flow at stake (oil being $75/barrel), payment of an amount of $90,150 was missing.

It was a disclosure when we figured out the purchaser had not represented the numbers appropriately for 9 days. Our client (the company) had transparent, defensible, and time-stamped sensor data, for which they asked the purchasers to provide proof and paperwork for the same. The purchaser furnished the data except for those 9 days. It was found out that their pipeline & tank measurement systems were not functional for which they entered the data manually. After this disclosure, the buyer had to remunerate the remainder of the amount that they didn't pay.